Introduction

I worked in The Radar Research Lab, located in School of Interdisciplinary Engineering and Sciences (SINES) in National University of Science and Technology (NUST). There were two projects at that time, that were being worked on - One was Saferail Project, while the other was confidential project. Major focus was being done on the Saferail project.

Saferail Project was a collaboration between the said lab and Pakistan Railways to make the railway network of Pakistan more secure. The idea was to mount a camera in front of trains to automatically inform the driver and/or stop the train in case of presence of an obstacle in front of the train.

The major role was played by object detection by an onboard computer.

The major role was played by object detection by an onboard computer.

Major Activities

I was mainly responsible for the following activities:

1- Onsite Testing

The onsite Testing of the camera was performed on a scaled version of a train. Such type of trains are usually used to check out the tracks occasionally for obstacles. The scaled train was deployed and onsite vibrations were observed and object detection data was trained.

The camera was mounted on top of the scaled train and the testing was performed.

2- Vibrations Testing

The Vibrations were tested on the scaled train. Vibrations were studied on top of a bus initially.

Vibrations testing was also performed on a vibration bed prior to deploying on the scaled train.

The random PSD vibration of the frame:

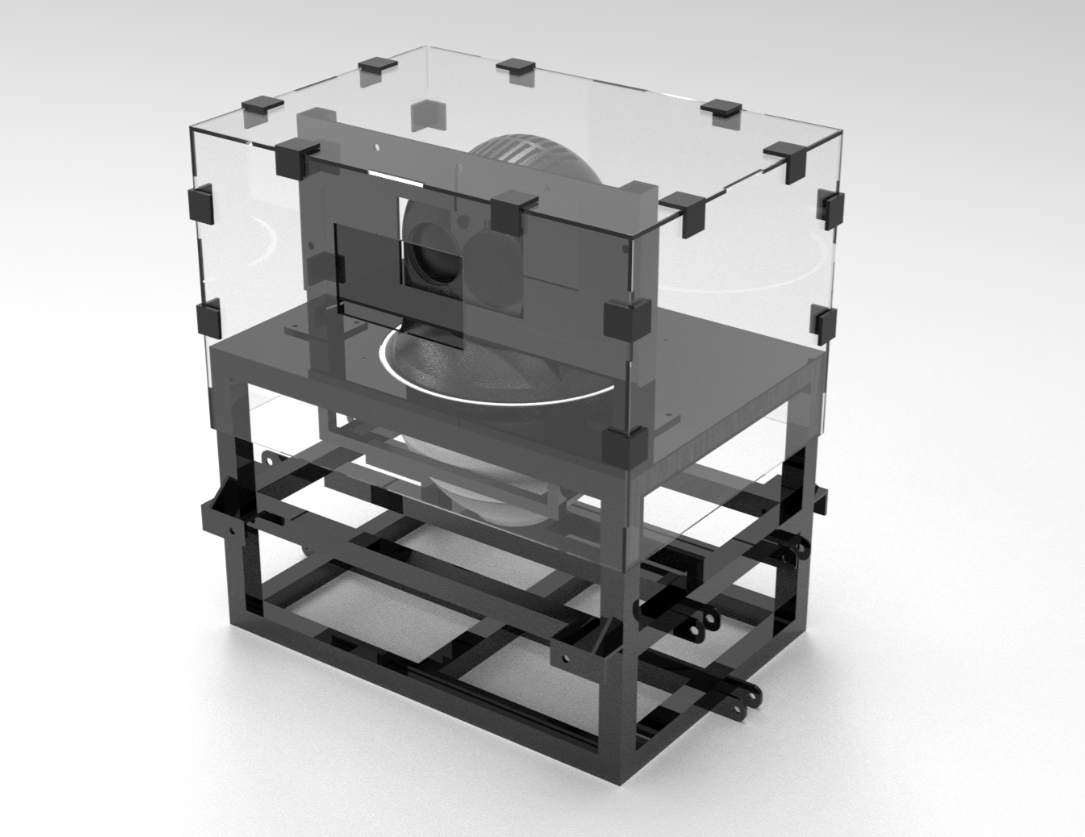

3- Enclosure Design

The camera and the PCBs and control boards needed an enclosure. The dimensions were to be minimized, while making the enclosure in a modular design. Following are some iterations of the enclosure design.

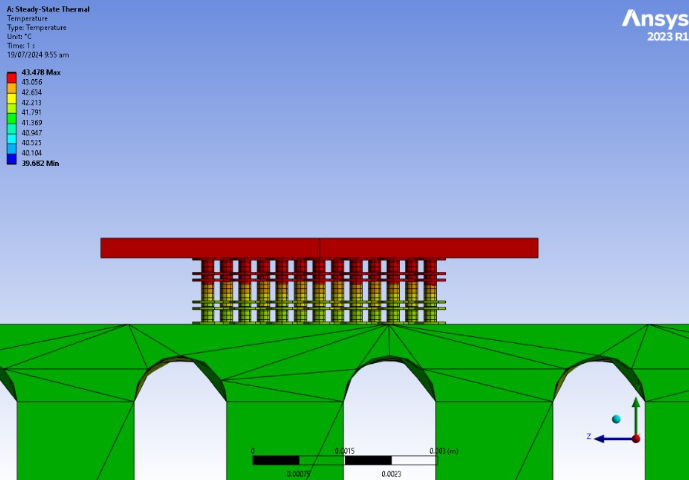

4- Thermal Analysis

For analyzing the thermal effect on the enclosure, Thermal analysis were performed on the enclosure. During the time I was present in the lab, only the idea of thermal cooling was designed for the whole enclosure.

Besides the whole enclosure thermal analysis, the analysis of individual PCBs was also important. Vias were used in some of the PCBs to increase the thermal heat transfer.

5- CFD

To make the enclosure more aerodynamic, CFD was performed on some parts of the system.

6- Renderings

For presentations, and better visibility, renders of some parts were made.

Keyshot was used for most of the Renderings.

Certificate

RRL provides a certificate upon the completion of the internship program. here is my certificate:

Conclusion

This is one of the biggest projects that I was a part of. Working with the team at RRL really helped me to hone my skills and become more proficient in my field.

No comments:

Post a Comment